Productivity Measurement Analysis Using Multi Factor Productivity Measurement Model (MFPMM) At PT. Primabox Adiperkasa

Analisis Pengukuran Produktivitas Dengan Menggunakan Metode Multi Factor Productivity Measurement Model (MFPMM) Pada PT. Primabox Adiperkasa

DOI:

https://doi.org/10.21070/pels.v2i2.1250Keywords:

Index Productivity, Productivity, Productivity Multi-Factor MeasurementAbstract

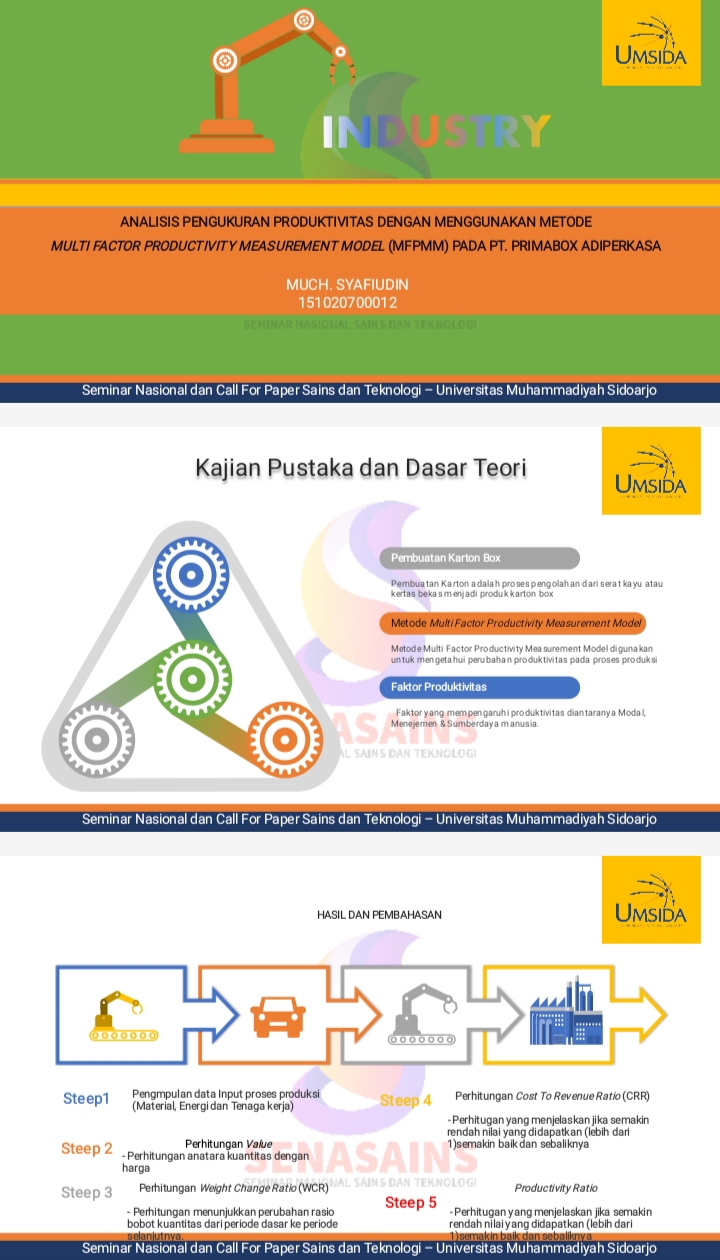

PT Primabox Adi Perkasa is a company located on Jl. Jaksa Agung Suprapto, Sumber Gedang, Pandaan, Pasuruan. This company is engaged in manufacturing, namely the production of cardboard boxes. This company can produce up to 550,000 pcs of cardboard boxes per year, employing 300 employees. The problem that arises in the company is caused by changes in the price of raw materials or materials which make changes in costs that must be considered in the production proces. Measuring productivity by using the Multi-Factor Productivity Measurement Model (MFPMM). This method is used to make it easier to measure changes in previous performance, controllers, and controllers of current company performance and can assess and evaluate the effect of profitability resulting from changes in productivity.The results of the research on Productivity Measurement Analysis Using the Multi-Factor Productivity Measurement Model (MFPMM) obtained the productivity index of used cardboard 89.69%, glue 97.72%, electricity 100.79%, fuel 82.24%, oil 109.61%, and The workforce is 123.75%.

Downloads

References

J. dan N. S. Gunawan, Pengantar Teknik & Sistem Industri, 1st ed. Jakarta: Guna Widya, 2000.

A. . Nasution, Manajemen Industri. Yogyakarta: CV. Andi Offset, 2006.

F. . Noor, Ekonomi Manajerial. Jakarta: PT. Rajagrafindo Persada, 2008.

A. T. dan H. A. Nugroho, A., Ekonomi Manajerial. Jakarta: Raja grafindo Persada, 2016.

H. Purnomo, Pengantar Teknik Industri, 2nd ed. Yogyakarta: Graha Ilmu, 2004.

S. Reksohadiprodjo, Manajemen Produksi dan Operasi, 1st ed. Yogyakarta: BPFE, 1995.

F. . Sadikin, Trip dan Trik Meningkatkan Efisiensi, Produktivitas dan Profitabilitas. Yogyakarta: CV. Andi Offset, 2005.

D. dan A. I. Setyoningsih, Operaions Manajement, 7th ed. Jakarta: Salemba Empat Grand Wijaya Center, 2005.

M. Sinungan, Produktivitas Apa dan Bagaimana, 6th ed. Jakarta: Bumi Aksara, 2005.

S. Triandaru, Ekonomi Mikro. Jakarta: Salemba Emban Patria, 2001.

Soekartawi, Teori Ekonomi Produksi Dengan Pokok Bahasan Analisis Fungsi Cobb-Douglas. Jakarta: PT. Rajagrafindo Persada, 2003.

A. dan M. K. Syukron, Pengantar Teknik Industri. Yogyakarta: Graha Ilmu, 2010.

R. A. M. Puteri, “Pengukuran Produktivitas Parsial di PT. Aneka Cipta Sealindo,” J. Teknol., vol. 9, pp. 14–20, 2017.

I. F. Fithri, P, “Analisis Produktifitas Menggunakan Metode Objective Matrix (OMAX) pada PT. Maradon Berlin Sakti,” vol. 13, pp. 548–555, 2014.

Jono, “Analisis Produktivitas Pabrik Spiritus Menggunakan Fungsi Produksi Cobb-Douglas pada PT XYZ Yogyakarta,” Tek. Ind., vol. 14, pp. 109–230, 2016.

L. Y. Syarifudin, “Analisis Produktivitas Perusahaan Pada UD. Karya Jaya,” Tek. Ind., vol. 3, pp. 22–27, 2014.