Quality Control Design to Reduce Shoes Production Defects Using Root Cause Analysis and Lean Six Sigma Methods

Perancangan Pengendalian Kualitas Untuk Mengurangi Cacat Produksi Sepatu Menggunakan Metode Root Cause Analysis Dan Lean Six Sigma

DOI:

https://doi.org/10.21070/pels.v2i2.1242Keywords:

Quality Control, Root Cause Analysis, Lean Six SigmaAbstract

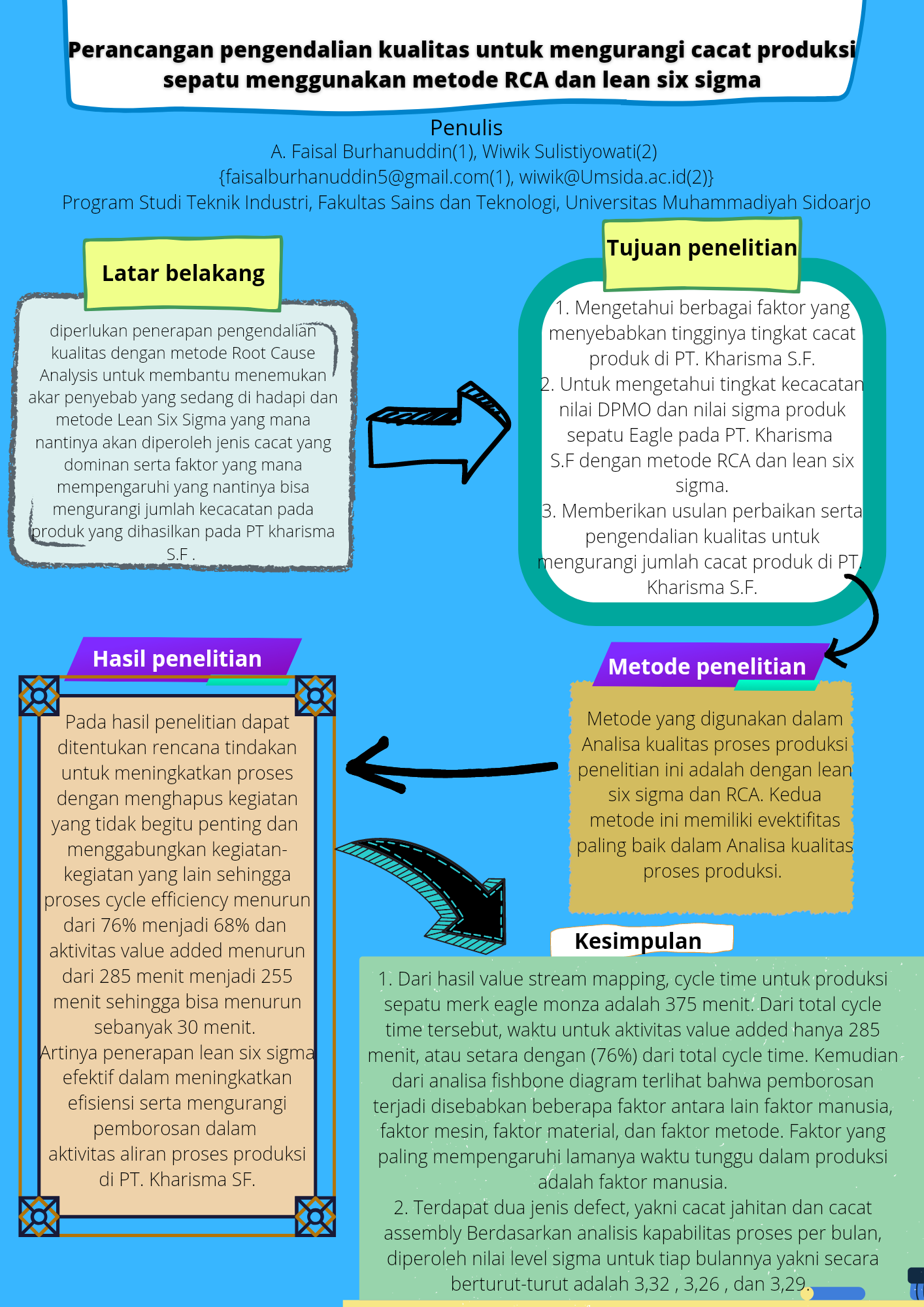

PT. Kharisma S.F is a company that produces sporty shoes with the Eagle, Nevada, and Fladeo brands. PT. Kharisma experienced a defect in the production process, which occurred in the sewing process and assembly process. However, the most common disability experienced by PT. S.F's charisma is a defect in the sewing process. This research focuses on the inspection of the production of Eagle brand shoes. With these problems, it is necessary to carry out quality control, which is useful for regulating the various products produced so that they can have good quality. To determine the level of a defect in the DPMO value and sigma value, to find out the various factors that cause the high level of product defects, and to provide suggestions for improvement and quality control to reduce the number of product defects, Root Cause Analysis (RCA) and Lean Six Sigma methods were used. Data were obtained from the company for three months and from 6 respondents to identify waste. From the results of research conducted. It can be seen that the factor that most influences the length of waiting time in production is the human factor. The highest identification of waste is defects. There are two types of defects, namely sewing defects and assembly defects. As for alternative improvements to reduce the number of defects, namely checking machine parts on the production floor with a checklist every day and replacing machine parts that are damaged or have expired, and providing regular training to operators scheduled once every three months.

Downloads

References

D. Ariani, “Pengendalian Kualitas Statistik (Pendekatan Kuantitatif dalam Manajemen. Kualitas),” Yogyakarta, Andi Offset, 2004, p. 364.

D. Yuswandi dan A. R. Dwicahyani, “Pengendalian Kualitas Produk Cacat Hollow Alumunium Menggunakan Metode Six Sigma dengan Tahapan DMAIC,” Seminar Nasional Teknologi Industri Berkelanjutan I (SENASTITAN I), 2021.

N. Susendi, Adrian dan I. Sopyan, “Kajian Metode Root Cause Analysis yang Digunakan dalam Manajemen Risiko di Industri Farmasi,” Majalah Farmasetika, p. 313, 2021.

A. F. Sanny, Mustafid dan A. Hoyyi, “Implementasi Metode Lean Six Sigma Sebagai Upaya Meminimalisasi Cacat Produk Kemasan Cup Air Mineral 240 Ml (Studi Kasus Perusahaan Air Minum),” JURNAL GAUSSIAN, vol. 4, p. 228, 2015.

S. D. Fitriani, M. Siswoyo dan Mahmudah, “Konsep Diri Mahasiwa Dalam Membentuk Loyalitas Merek Sepatu Converse,” JURNAL SIGNAL, p. 176, 2019.

A. F. Bilgies, “Peran Kualitas Produk, Harga Dan Kualitas Layanan Terhadap Kepuasan Pelanggan Billagio Skincare Clinic Sidoarjo,” EkoNiKa, p. 79, 2016.

A. Mas’amah dan Suhartini, “Implementasi Six Sigma Sebagai Pengendalian Kualitas Proses Pengelasan Replating Lambung Kapal KMP Nusa Sejahtera,” Seminar Nasional Teknologi Industri Berkelanjutan I (SENASTITAN I), p. 62, 2021.

H. Irawati, F. Kusnandar dan H. D. Kusumaningrum, “Analisis Penyebab Penolakan Produk Perikanan Indonesia Oleh Uni Eropa Periode 2007 – 2017 Dengan Pendekatan Root Cause Analysis,” Jurnal Standardisasi, p. 152, 2019.

Novan dan Suhartini, “Pengendalian Kualitas Menggunakan Pendekatan Six sigma Sebagai Upaya Perbaikan Produk Defect (Studi Kasus: Departemen Produksi PT. Semen Indonesia (Persero) Tbk,” Seminar Nasional Teknologi Industri Berkelanjutan I (SENASTITAN I), p. 250, 2021.

I. D. U. Adhika Nurlita, “Pengendalian Kualitas Produk Brake Lining Pada Formula Non-Asbase Dengan Metode Statistical Proses Control (SPC) dan Root Cause Analysis (RCA) Di Pt. Xyz Surabaya,” Jurnal MATRIK, pp. 1-12, 2019.