Facility Relayout Using Systematic Layout Planning and Blocplan Methods to Minimize Material Handling Distance

Relayout Fasilitas Menggunakan Metode Systematic Layout Planning dan Blocplan Guna Meminimasi Jarak Material Handling

DOI:

https://doi.org/10.21070/pels.v2i2.1231Keywords:

Activity Relationship Chart, Blocplan, Systemic Layout PlanningAbstract

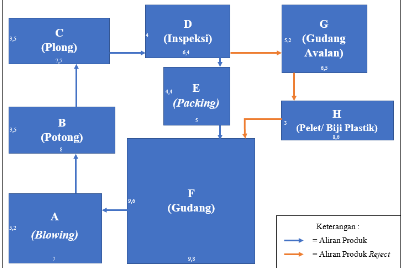

. A good facility layout will affect sustaining the smoothness of the production process. initial observation on a current CV. NTY is still not good to apply because it does not take into account the degree of proximity. This can be seen from machine laying as well as workstations that look distanced as well as the flow of intersecting material resulting in backtrackings, such as the blowing department towards the cutting department its material removal distance of 23.2 m and having to go through the packing department and plong department with too much distance and intersect caused the production time to become longer. The methods that production facility layout design uses on the CV. NTY is Systematic Layout Planning and Blocplan methods. This method was chosen because it conforms to the company's characteristics and can minimize the distance between production stations as well as no more intersecting production process flow. This study was conducted to find out and obtain improved material distance efficiency in handling the preliminary layout with the proposed layout. The results of the study show the blocplan method has a total decrease in the displacement distance smaller by 60.73 m with an efficiency increase of 42 % as well as improving the flow of the production process in the initial layout.

Downloads

References

I. Rahayu, Praktis Belajar Kimia. 2007.

F. Nurhidayat, “Usulan Perbaikan Tata Letak Fasilitas Lantai Produksi Dengan Metode Systematic Layout Planning (SLP) di PT DSS,” vol. 5, no. 80, pp. 9–16, 2021.

E. Hartari and D. Herwanto, “Perancangan Tata Letak Stasiun Kerja dengan Menggunakan Metode Systematic Layout Planning Work Station Layout Design Using the Systematic Layout Planning Method,” vol. 5, no. 2, pp. 118–125, 2021.

N. M. Iskandar, “Perancangan Tata Letak Fasilitas Ulang (Relayout) Untuk Produksi Truk Di Gedung Commercial Vehicle (CV) Pt. Mercedes- Benz,” vol. XI, no. 1, pp. 66–75, 2017.

M. Anik and A. D. W. I. Wibowo, “Mengurangi Ongkos Material Handling Melalui Perbaikan Layout Menggunakan Systematic Layout Planning (SLP) Reduce Material Handling Cost Through Improvement,” pp. 40–47, 2020.

A. D. Budianto and A. S. Cahyana, “Re-layout tata letak fasilitas produksi imitasi pvc dengan menggunakan metode systematic layout planning dan blocplan 1,2,” no. 2, pp. 23–32, 2021.

F. T. Kebela, B. Suhardi, and C. N. Rosyidi, “Perbaikan Tata Letak Fasilitas Produksi Incoming Material Menggunakan Systematic Layout Planning di PT. Pan Brothers Tbk Boyolali,” Performa Media Ilm. Tek. Ind., vol. 19, no. 1, pp. 77–84, 2020, doi: 10.20961/performa.19.1.40093.

F. L. Camerawati and H. Handoyo, “Gudang Bahan Baku Dengan Metode Systematic Layout Planning (SLP),” vol. 02, no. 03, pp. 59–70, 2021.

A. Y. Pratama and A. Arista, “Perancangan Ulang Layout Proses Produksi Pada PT XYZ,” vol. 03, 2021.

R. K. Abdurrahmad. Muhammad Milzam, “Rancang Ulang Tata Letak Fasilitas Produksi untuk Efisiensi Produksi Kopi di PT Sinar Mayang Lestari Menggunakan Metode Systematic Layout Planning dan Software Blocplan,” vol. 32, no. 2, pp. 146–157, 2021.