Dust Cleaning System on Panel PET Preform Injection Machine BM500

Sistem Pembersih Debu Pada Panel Mesin Injection Preform PET BM500

DOI:

https://doi.org/10.21070/pels.v2i2.1277Keywords:

Compressed Air, Dust, Humidity, TemperatureAbstract

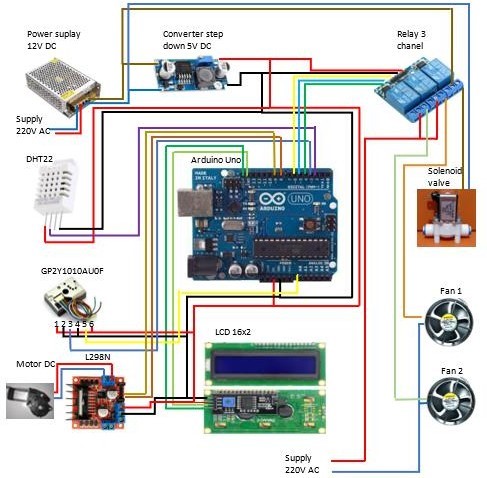

Dust Cleaning System on Panel Injection Machine BM500 PET preforms. The clean machine panel is essential so that performance and safety are maintained. Dust that sticks to electrical components such as contactors, servo drives, solid-state relays, PLCs, and several other components causes overheating. Dust attached to the conductors of electrical components will burn and become carbon which bridges the emergence of sparks. To reduce the risk of damage to electrical equipment on the injection machine, an automatic dust cleaning system is designed. This system uses a GP2Y1010AU0F dust sensor, a DHT 22 sensor to detect temperature and humidity, Arduino Uno microcontroller, 16x2 LCD, L298N driver, DC motor, fan, solenoid valve and utilizes high-pressure air to spray dust inside the panel which is then sucked in with a fan and collected in a dust bag. From the results of the trial installation of this system with 10 times of data collection for 4 hours 30 minutes with an interval of 30 minutes, it can be seen that the dust cleaning process runs 2 times. After the cleaning process is running the data shows that the dust density can drop to 0.16 mg/m³. Likewise, the temperature inside the engine panel, after the air circulation process runs well in the first or second conditions, the temperature inside the panel can drop below 40°C. From the test results, it can be seen that the system can work well.

Downloads

References

A. Solih and J. Jamaaluddin, “Rancang Bangun Pengaman Panel Distribusi Tenaga Listrik di Lippo Plaza Sidoarjo Dari Kebakaran Berbasis Arduino Nano,” JEEE-U (Journal Electr. Electron. Eng., vol. 1, no. 2, pp. 61–68, 2017.

F. Ardiansyah, Misbah, and P. P. S., “Sistem Monitoring Debu dan Karbon Monoksida Pada Lingkungan Kerja Boiler Di Pt. Karunia Alam Segar,” IKRA-ITH Teknol. J. Sains Teknol., vol. 2, no. 3, pp. 62–71, 2018.

T. Liu, “Digital-Output relative humidity & temperature sensor/module DHT22,” New York Aosong Electron., vol. 22, pp. 1–10, 2015.

SHARP, “GP2Y1010AU0F Compact Optical Dust Sensor,” Datasheet, pp. 1–11, 2017, [Online]. Available: http://www.sharpsme.com/download/gp2y1010au-epdf.

G. W. Pambudi, Belajar Arduino from Zero to Hero, no. ISSN 2442-7659. 2020.

S. M. Tua, Suhardi, and A. Fathudin, “EVALUASI KINERJA PERALATAN AIR DRYER DESICCANT,” pp. 259–270, 2018.

P. A. Sunarya, N. Rahayu, and F. Yono, “Prototype Robot Pembersih Serbuk Kayu Berbasis Arduino Menggunakan Smartphone Android,” ICIT J., vol. 6, no. 2, pp. 163–172, 2020.

D. S. Muzakki, “Rancang Bangun Monitoring Temperatur Pendeteksi Debu pada Panel Berbasis Arduino Uno,” Din. Inform. Vol., 2018.

C. Optical and D. Sensor, “GP2Y1010AU0F,” pp. 1–9, 2006.

S. Syahrorini, D. H. R. S, P. Studi, T. Elektro, and U. M. Sidoarjo, “Aplikasi alat ukur partikulat dan suhu berbasis iot,” vol. 25, no. 1, pp. 1–9, 2020.