IoT-Based Car Monitoring Engine Mounting Design

Rancang Bangun Monitoring Engine Mounting (Bantalan Mesin) Mobil Berbasis IoT

DOI:

https://doi.org/10.21070/pels.v2i2.1190Keywords:

Engine Mounting, iot, sound sensors, temperature sensors, vibration sensorsAbstract

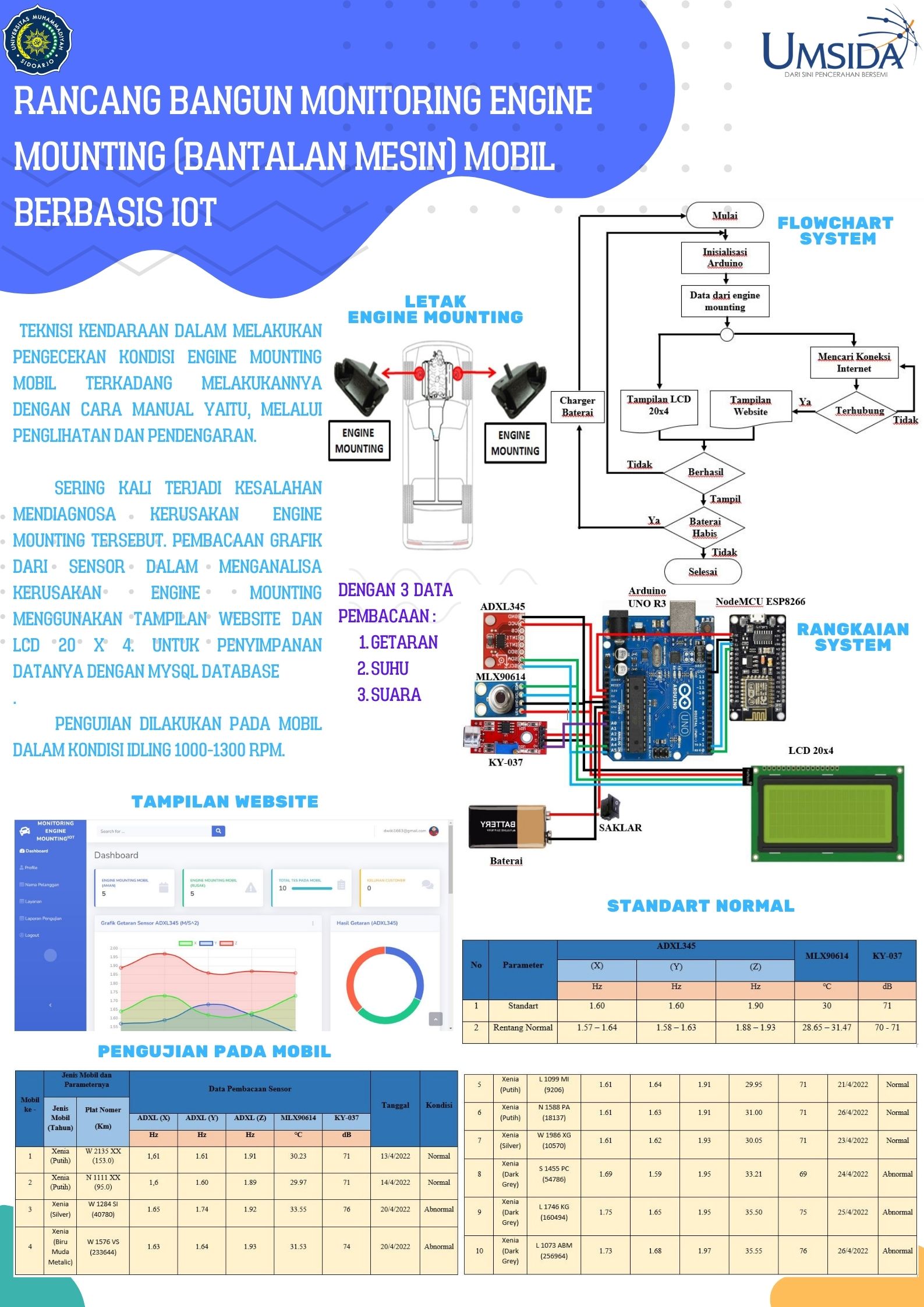

Vehicle technicians in checking the condition of the car's engine mounting do it manually, namely, through sight and hearing. This kind of manual method often makes an error in diagnosing engine mounting damage, because each individual has a different level of hearing and vision sensitivity. This research aims to make it easier for technicians to check the feasibility level of engine mounting with accurate data. This tool is based on IoT technology, where the reading of graphs from sensors in analyzing engine mounting damage using a website display and a 20 x 4 LCD. For its data storage with MySQL Database. In its working principle, it uses the K-Nearest Neighbor (KNN) algorithm method, in order to distinguish between engine mounting that is still good and damaged. Graph readings based on normal and abnormal range data from the data retrieval of the engine mounting of the new unit car. The vibration sensor used is the ADXL345 and also several other sensors such as the temperature sensor (MLX90614) and the sound sensor (KY-037). It uses the Arduino UNO R3 microcontroller and the Esp8266 NodeMCU as a data sender to the server. Tests were carried out on cars in idling conditions of 1000-1300 rpm. From the results of the study produced standard feasibility for vibrations from 3 axes (x = 1.60 ; y = 1.60 ; z = 1.90), temperature = 30 °C, Sound = 71 dB.

Downloads

References

S. Bahri and P. S. Yuza, “Analisa Kerusakan (Deformasi) Engine Mounting Kendaraan Toyota Agya Berdasarkan Tingkat Vibrasi Berbasis MEM Accelerometer,” Resist. (Elektronika Kendali Telekomun. Tenaga List. Komputer)., vol. 2, no. 2, pp. 131–136, 2019.

M. D. Pratama, “Desain dan Pembuatan Alat Monitoring Kerusakan Mesin Berdasarkan Level Getaran,”

Rekayasa Mesin., vol. 11, no. 1, pp. 21–29, 2020.

W. Naibaho, S. Siahaan, and R. Naibaho, “Analisa Perbandingan Putaran Mesin Untuk Kompresor Air Condition Pada Mobil Daihatsu Taruna Terhadap Karakteristik Getaran Berdasarkan Time Domain,” J. Mesil (Mesin, Elektro, Sipil,)., vol. 2, no. 1, 2021.

A. H. Listiyono, Nurhadi, “Optimalisasi Tekanan Shock Absorber Dan Tekanan Pegas Coil Terhadap Getaran Mobil,” JETM J. Energi dan Teknol. Manufaktur., vol. 03, no. 01, pp. 5–10, 2020.

Z. Abidin, J. T. Mesin, U. Sriwijaya, A. S. Getaran, A. Orbit, and A. Fase, “Perancangan Alat Ukur Getaran Untuk Mendeteksi Kerusakan Pada Bantalan,” J. REKAYASA MESIN., vol. 18, no. 2, pp. 69–78, 2018.

T. Wibowo, I. Isranuri, S. Abda, M. Sabri, and A. Hamsi, “Studi Eksperimental Sinyal Vibrasi Untuk Mendeteksi Jenis Kerusakan Bearing Ucp-204,” J. e-Dinamis., vol. 6, no. 2, pp. 35–48, 2018.

N. R. Setyoningrum, A. Saputra, S. Tinggi, T. Indonesia, and E. Mounting, “Sistem Pakar Deteksi Kerusakan Engine Mounting Pada Kendaraan Bermotor Roda Empat Menggunakan Metode Certainty Factor,” JURTIK J. Teknol. Inf. dan Komunikasi., vol. 8, no. 2, pp. 2–5, 2019.

D. Meidiasha, M. Rifan, and M. Subekti, “Alat Pengukur Getaran, Suara Dan Suhu Motor Induksi Tiga Fasa Sebagai Indikasi Kerusakan Motor Induksi Berbasis Arduino,” J. Electr. Vocat. Educ. Technol., vol. 5, no. 1, pp. 27–31, 2020.

S. Harianto, A. B. Setiawan, and A. P. Sari, “Studi Tentang Penggunaan Metode Scanning Pada Sistem Telemetri Pendeteksi Kerusakan Air Conditioner Kendaraan,” Elektrika, vol. 01, no. 01, pp. 47–51, 2017.

. A. Wisaksono, Y. Purwanti, N. Ariyanti, M. Masruchin, et al, “Design of Monitoring and Control of Energy Use in Multi-storey Buildings based on IoT,” JEEE-U (Journal Electr. Electron. Eng. UMSIDA, vol. 4, no. 2, pp. 128–135, 2020.

A. Rahardi, S. Karim, B. Darmajaya, J. Za, P. Alam, and N. L. Ratu, “Sistem Pakar Berbasis Web untuk Mendiagnosis Mesin Mobil dengan Metode Forward Chaining,” Teknika, vol. 14, no. x, pp. 51–56, 2020.

N. Febriyanto, C. Rahmad, and C. Bella Vista, “Deteksi Kerusakan Dan Kelayakan Ban Mobil Berdasarkan Ekstraksi Tekstur Menggunakan Gray Level Cooccurrence Matrix Dengan Metode Jaringan Syaraf Tiruan,”

J. Inform. Polinema, vol. 7, no. 4, pp. 27–32, 2021.

H. Pratiwi, “Sistem Pakar Diagnosa Kerusakan Mobil Menggunakan Metode Case Based Reasoning Berbasis Visual Basic,” Digilib.Mercubuana.Ac.Id, vol. V, no. 2, 2013.

F. W. Perdana, S. D. Ayuni, A. Wisaksono, and S. Syahrorini, “Prototype Social Distancing Reminder Using HC-SR04 Sensor at The Payment Counter via a Smartphone,” Procedia Eng. Life Sci., vol. 1, no. 2, 2021.

A. Wisaksono and C. A. Ragil, “Design and Development of Parking Motor Parking Information System at Muhammadiyah University, Sidoarjo,” IOP Conf. Ser. Mater. Sci. Eng., vol. 874, no. 1, 2020.