Carbide Tool Wear Analysis for Manufacturing Aisi 4140 Alloy Steel with 2D/3D Deform Simulation in PT Rejeki Sekawan Abadi

Analisis Keausan Pahat Karbida Untuk Membubut Baja Paduan Aisi 4140 Dengan Simulasi Deform 2D/3D di PT Rejeki Sekawan Abadi

DOI:

https://doi.org/10.21070/pels.v2i2.1222Keywords:

Alloy Steel, Carbide, Feed Rate, Lathe, Tool WearAbstract

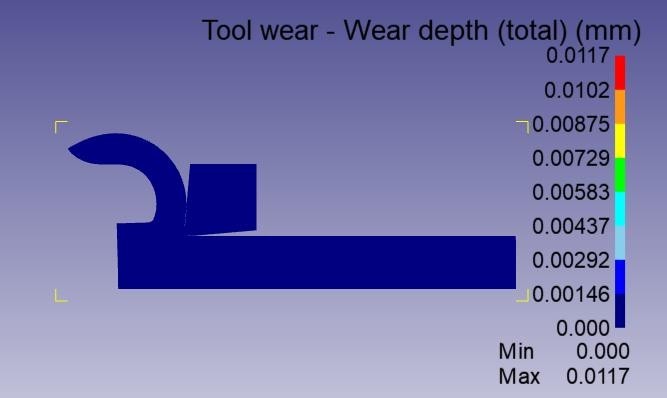

The lathe process is a machining process that is most widely used and is very commonly used in an industrial field. During the turning process, the lathe will cut the workpiece with the main movement being rotating so that the workpiece can be slowly reduced in diameter. There are several parameters in the turning process such as feed rate, cutting speed and cutting depth. Parameter optimization in the cutting process is very necessary in order to reduce the cutting force during the machining process. If the cutting force is high, it can cause the tool ability to be reduced. In this study using three turning parameters, namely spindle rotation rate, feeding depth, and feed or chisel distance in 1 rotation of the workpiece. This can be seen from the simulation results, the results of simulation-2 and simulation-4 with a feed rate of 0.1 mm/rad with two other different parameters, the value of the depth of tool wear is 0.00487 and 0.00410 mm, then in simulation-1 and simulation -3 with the same feed rate value of 0.2 mm/rad and with two other different parameters, the depth of tool wear is 0.0117 and 0.00932 mm, respectively. With these results, it can be seen that the feed rate has quite an effect on the depth of tool wear during the turning process. Based on the results of the study, it can be concluded that the variation of the parameters that are simulated in the turning process can affect the condition of the tool blade used. When running the machining process with inappropriate parameters, it will cause tool failure or tool blade damage. Therefore, the lathe parameters must be considered.

Downloads

References

J. Junaidi, “Analisa Perhitungan Gaya Potong Pada Proses Pembubutan Terhadap Material Dengan Pahat Carbide Menggunakan Karakteristik,” Seminar Nasional Teknik (SEMNASTEK) UISU, vol. 2, no. 1, pp. 227–233, May 2019, Accessed: Aug. 04, 2022. [Online]. Available: https://jurnal.uisu.ac.id/index.php/semnastek/article/view/1318.

S. Sunarto and S. Mawarni, “Pengaruh Pemesinan Laju Tinggi Keadaan Kering Terhadap Pertumbuhan Aus Sisi (VB) Pahat Karbida Berlapis (Tialn/Tin) Pada Pembubutan Paduan Aluminium 6061,” JPL, vol. 16, no. 2, p. 51, Aug. 2018, doi: 10.30811/jpl.v16i2.587.

B. T. Yuriko, “Analisis Pengaruh Hardening Dan Tempering Temperatur 5500c, 6000c, 6500c Pada Baja Aisi 4140 Terhadap Sifat Mekanis,” Skripsi, Institut Teknologi Nasional, 2020. Accessed: Aug. 04, 2022. [Online]. Available: http://eprints.itn.ac.id/4914/.

W. Widarto, B. S. Wijanarka, P. Paryanto, and S. Sutopo, TEKNIK PEMESINAN, vol. 1. Jakarta: Direktorat Jenderal Manajemen Pendidikan Dasar dan Menengah Direktorat Pembinaan Sekolah Menengah Kejuruan Departemen Pendidikan Nasional, 2008..

A. Kardi and I. Thamrin, “Pengaruh Kecepatan Potong dan Kedalaman Pemakan Terhadap Keausan Tepi Pahat Karbida Pada Proses Bubut Menggunakan Material Baja Karbon Rendah,” Sriwijaya University Repository, 30-Jul-2020. Accessed: Aug. 04, 2022 [Online]. Available: http://repository.unsri.ac.id/id/eprint/58968.

M. M. Rozaq and I. Iswanto, “Analisa Pengaruh Gerak Makan Dan Putaran Spindel Terhadap Keausan Pahat Pada Proses Bubut Konvensional,” R.E.M. (Rekayasa Energi Manufaktur) Jurnal, vol. 2, no. 1, p. 13, Aug. 2017, doi: 10.21070/r.e.m.v2i1.842..

S. M. L. Gambeh, R. Poeng, and I. R. Rondonuwu, “Pengaruh Kecepatan Potong Terhadap Temperatur Pemotongan Pada Proses Pembubutan,” JURNAL POROS TEKNIK MESIN UNSRAT, vol. 4, no. 2, Nov. 2015, Accessed: Aug. 04, 2022. [Online]. Available: https://ejournal.unsrat.ac.id/index.php/poros/article/view/9783.

B. Siswanto and S. Sunyoto, “Pengaruh Kecepatan dan Kedalaman Potong pada Proses Pembubutan Konvensional Terhadap Kekasaran Permukaan Lubang,” J. Din. Vok. Tek. Mesin, vol. 3, no. 2, pp. 82–86, Oct. 2018, doi: 10.21831/dinamika.v3i2.21403.

C. I. P. K. Kencanawati, Proses Pemesinan, vol. 1. Denpasar: Universitas Udayana, 2017..

Z. Zulfahmi, “Analisa Keausan Pahat Bubut Sebelum dan Sesudah Dikarburasi Menggunakan Serbuk Arang Cangkang Kelapa Sawit,” Undergraduate Thesis, Universitas Muhammadiyah Sumatera Utara, MEDAN, 2017. Accessed: Aug. 04, 2022. [Online]. Available: http://repository.umsu.ac.id/handle/123456789/13106.

A. R. Nasution, W. Septiawan Damanik, and A. A, “Analisa Gaya Potong Pada Proses Pemesinan Turning Menggunakan Bahan Politetrafluoroetilena (PTFE)”, SiNTESa, vol. 1, no. 1, pp. 652–661, Aug. 2021.